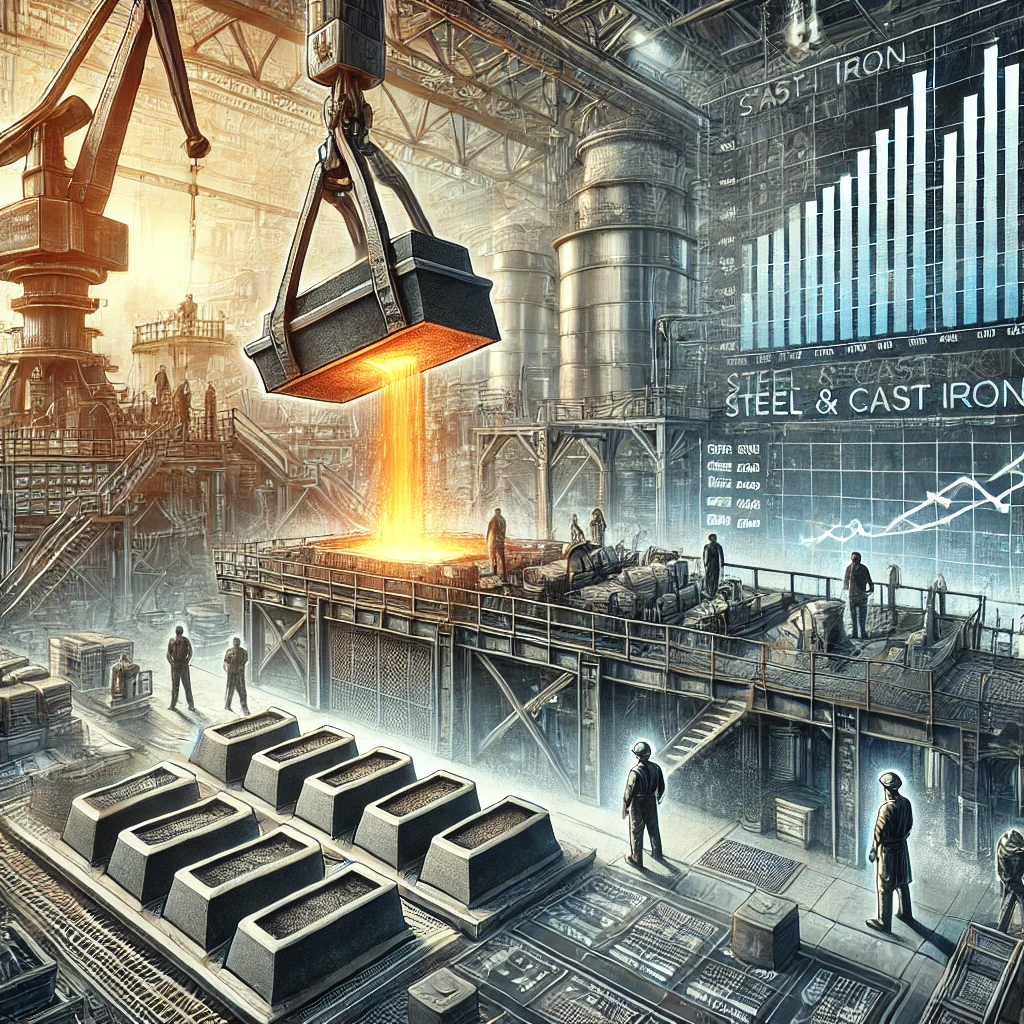

The prices at which cast iron and steel ingots are available define a large part of manufacturing, construction, and the automotive industry. These materials are also the backbone for creating strong, high-performance components. It is important for companies to understand the factors that govern their pricing, such as demand, supply, and cost of production, so that informed decisions can be made.

Trends Currently in Cast Iron Price

Cast iron, hailed as one of the strongest and most versatile materials, serves as a foundation for most industrial applications. At the same time, recent steel prices in India, including cast iron price, are highly influenced by the global influences on the market of iron and steel, energy, and transport costs. According to The Business Research Company, the increasing need for iron and steel castings in construction and heavy machinery sectors propels price fluctuations.

Policies of the government and infrastructure investments have also been major stabilizing or increasing factors in cast iron prices. For instance, with India’s emphasis on increasing domestic production, pricing might trend upwards, though this upward trajectory will be periodically skewed by supply chain disturbances worldwide.

Insights on Steel Ingot Price

Steel ingots are essential materials for the manufacture of high-grade steel products. Another important commodity in the metal industry is steel ingots.” According to Verified Market Research, demand is thus increasing in steel ingots found in construction and automotive.

Accordingly, raw material availability and production cost determine ingot price today“.

Ingot price influences include environmental rules and energy costs for producing steel. Monitoring a reliable steel price prediction in India helps businesses forecast such trends for effective budgeting and procurement strategies.

Factors Affecting Prices

Cost of Raw Materials: Fluctuations in prices of scrap metal and ores of iron directly affect prices of cast iron and steel ingots.

World Demand: The activities in the economy, especially one as large as that of China, might touch off a reaction concerning world steel prices and thus availability in India too.

Exchange Rate of the Currency: Fluctuation in the price of the Indian Rupee as compared to prominent currencies will affect the cost of raw materials imported.

Government Policies: Import and export tariffs, subsidies, and important restrictions will all affect the pull and push balances of price.

The Importance of Forecasting in Price Decisions

Understanding the current steel prices in India is just about all that a business using steel would require. Steel price prediction in India through the use of tools and experts’ insights is, however, very important for navigating price changes. Therefore, accurate forecasting fortifies procurement strategies against unexpected market volatility to manage costs associated with market fluctuations.

Keeping platforms like Verified Market Research and The Business Research Company, you can even gain knowledge of the pricing patterns and developments in the market stage. Based on these updates, companies can even process data-driven decisions that add to their profits.

Conclusion

The cast iron and steel ingot markets are quite significant contributors to the industry growth in India. Regular monitoring of current steel prices in India and using the best and most reliable steel price prediction in India helps businesses keep themselves ahead in an ever-changing competitive market. The industries must also understand the factors influencing cast iron and ingot pricing to avail themselves of optimal operations, lower costs, and greener growth.

For detailed reports and expert analysis on trends in the market, Verified Market Research and The Business Research Company prove to be useful in providing critical data, facilitating industries, and making it easier for them to reap the benefits of the more complex nature of global and local markets.