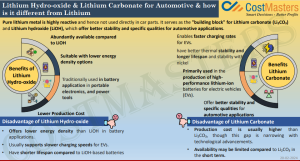

Pure lithium metal is highly reactive and hence not used directly in car parts. It serves as the “building block” for Lithium carbonate (Li₂CO₃) and Lithium hydroxide (LiOH), which offer better stability and specific qualities for automotive applications. These compounds are preferred for automotive applications because they provide enhanced stability and possess specific qualities essential for ensuring the safety and performance of electric vehicles.

Benefits of Lithium Hydro-oxide

- Abundantly available compared to LiOH: Lithium hydroxide (LiOH) plays a crucial role in various applications, its availability is not as abundant compared to other materials. This scarcity can pose challenges, especially as demand for LiOH continues to rise in sectors like battery production. In contrast, the material mentioned alongside “LiOH” is significantly more abundant, making it a potentially more reliable and readily available option for various industrial processes. This abundance can offer several advantages, including potentially lower costs and a reduced risk of supply chain disruptions. Additionally, considering the current landscape of lithium prices, the material’s abundance becomes even more significant in ensuring cost-effectiveness and sustainability in production processes.

- Suitable with lower energy density options: While high energy density batteries offer benefits like longer range and smaller size, they may not be suitable for all applications. In such cases, exploring the suitable with lower energy density options becomes crucial. This could involve prioritizing factors like safety, cost, or specific performance requirements even if it means sacrificing some range or compactness. For instance, electric buses or stationary energy storage systems might prioritize safety and stability over maximizing range, opting for batteries with lower energy density but proven safety records. Similarly, cost-conscious applications like low-range electric scooters or budget electric vehicles might benefit from lower energy density batteries that offer affordability while meeting their intended use case. Ultimately, choosing the suitable option involves carefully balancing various factors beyond just energy density to ensure the battery aligns with the specific needs and priorities of the application.

- Traditionally used in battery application in portable electronics, and power tools: While its applications are expanding, lithium hydroxide boasts a strong legacy in the battery world. Traditionally, it has been a key component in batteries powering portable electronics like laptops and smartphones, as well as providing the muscle for power tools like drills and saws. Its ability to deliver reliable performance and long life cycles has made it a trusted choice in these demanding applications.

- Lower Production Cost: Beyond its improved battery performance, lithium hydroxide boasts a potential economic advantage that is lower production cost. Compared to the traditional lithium carbonate, lithium hydroxide production can potentially be streamlined, particularly when using spodumene as the raw material. This can translate to cost savings for battery manufacturers, potentially leading to more affordable batteries for consumers in the long run. However, it is important to note that this cost advantage depends on various factors and ongoing advancements in production technologies.

Disadvantage of Lithium Hydro-oxide

- Offers lower energy density than LiOH in battery applications: While offering several advantages, lithium hydroxide (LiOH) has one key drawback compared to its close chemical cousin, lithium hydroxide (LiOH): lower energy density in battery applications. This translates to shorter potential range or requiring larger batteries for similar range in electric vehicles. This lower energy density, despite other benefits, might make LiOH less suitable for applications where maximizing range or minimizing battery size is a top priority, such as long-range electric cars or drones.

- Usually supports slower charging speeds for EVs: One drawback of lithium hydroxide batteries, especially when compared to other lithium-ion battery chemistries, is their generally slower charging speeds for electric vehicles (EVs). This can be a disadvantage for users who need quicker turnaround times between charges, impacting the overall convenience and practicality of the vehicle. While research and development are ongoing to improve charging speeds in lithium hydroxide batteries, it is currently a factor to consider when evaluating their suitability for specific EV applications.

- Have shorter lifespan compared to LiOH-based batteries: A potential disadvantage of Lithium Hydroxide (LiOH) is its shorter lifespan compared to Lithium Carbonate (Li2CO3)-based batteries. While LiOH offers advantages like higher capacity and improved efficiency, it may degrade faster over time, potentially impacting the battery’s overall life and requiring earlier replacement. This can be a crucial factor for applications requiring long-lasting performance and high cycle stability, such as electric vehicles or grid storage systems.

Benefits Lithium Carbonate

- Enables faster charging rates for EVs: One significant benefit of Lithium Carbonate is its ability to enable faster charging rates for Electric Vehicles (EVs). This is because Lithium Carbonate facilitates the movement of lithium ions within the battery, allowing for quicker charging and shorter waiting times. This faster charging capability can significantly enhance the user experience and address range anxiety, a major concern for many potential EV adopters. As a result, Lithium Carbonate plays a crucial role in driving the wider adoption of EVs and promoting sustainable transportation solutions.

- Have better thermal stability and longer lifespan and stability with nickel: Lithium carbonate offers several advantages, particularly when combined with nickel in battery technology. It boasts superior thermal stability, meaning it can withstand higher temperatures without compromising performance or safety. This is crucial for ensuring battery reliability and longevity. Additionally, lithium carbonate contributes to a longer lifespan and improved stability when paired with nickel in the battery composition. This synergistic effect translates to batteries that last longer and maintain consistent performance throughout their life cycle. These combined benefits make lithium carbonate a valuable component in modern battery technology.

- Offer better stability and specific qualities for automotive applications: Lithium carbonate plays a critical role in the electric vehicle revolution as the primary ingredient for high-performance lithium-ion batteries. These batteries power EVs, enabling them to achieve longer ranges, faster acceleration, and improved efficiency compared to traditional gasoline-powered vehicles. The high energy density offered by lithium carbonate allows for the creation of compact and lightweight batteries, crucial for maximizing driving range and vehicle design flexibility. As the demand for EVs continues to surge, lithium carbonate remains a vital component in powering the future of sustainable transportation.

Disadvantage of Lithium Carbonate

- Production cost is usually higher than Li₂CO₃, though this gap is narrowing with technological advancements.

- Availability may be limited compared to Li₂CO₃ in the short term.